Cleaning

Before you even thinking about beat error, the watch needs to be serviced and oiled.

Fault location and diagnostics is waste of time on a dirty movement

Testing balance

The balance wheel should oscillate smoothly and freely. If it moves in a jerky, staccato manner, it likely indicates that it’s not concentric or flat.

Addressing this issue should be the first step before tackling the beat error.

For watches with a frequency of 18,000 bph, the balance wheel should oscillate for a minimum of 30-40 seconds. With higher frequencies, the oscillation duration will be shorter.

Checking the terminal curve

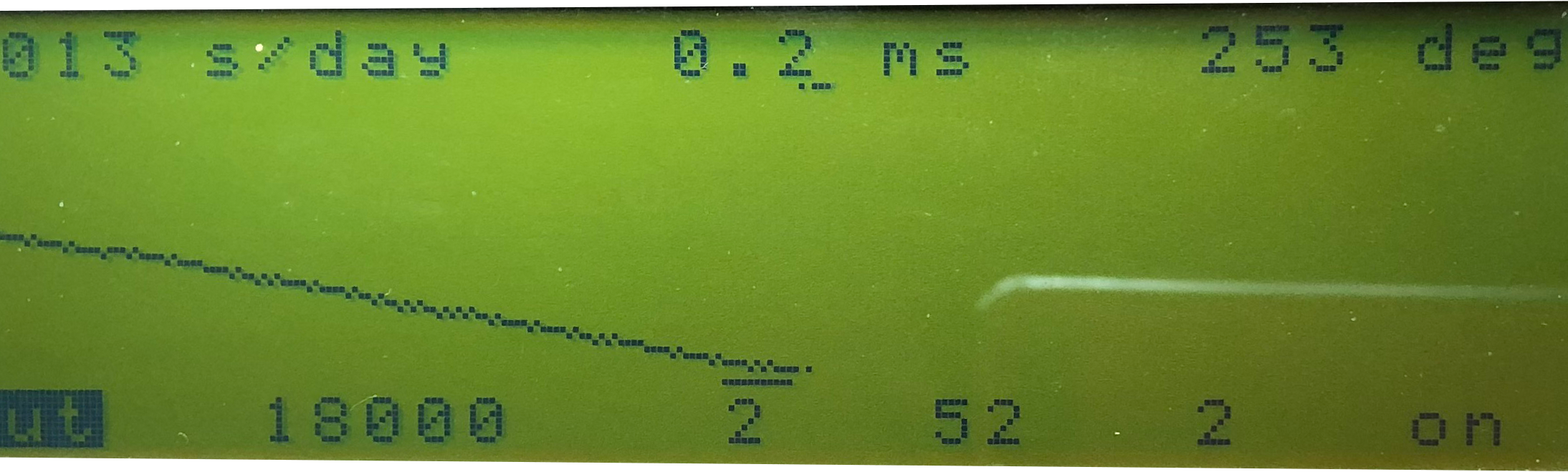

The final step is to check the terminal curve. As you adjust the regulator, the beat error should remain stable. If it varies by more than a few milliseconds, then you’ll need to tweak the curve accordingly.

Also, be aware that a spring that’s not flat or is out of round can affect the watch’s amplitude.

Tolerances

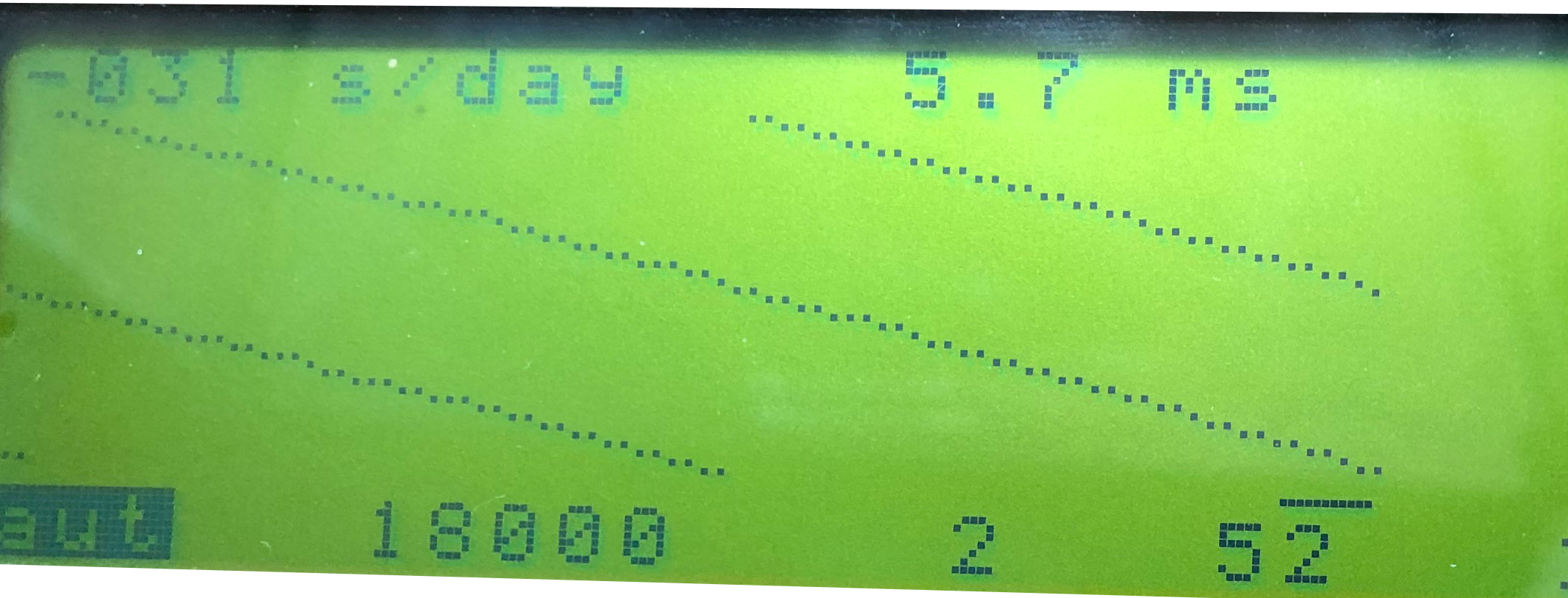

An informal rule suggests that for balances with fixed stud holders, the beat error should not exceed 1.0 ms, and for those with movable stud holders, it should be kept ≤ 0.3 ms.

A beat error less than 1.0 ms will not affect the watch’s timing.

The aforementioned steps are applicable to both fixed and movable stud holders. From this point forward, the focus will be on the fixed stud holder.

After removing the balance wheel, you need to mark where the stud is as a reference point.

This watch had a beat error around 3 ms and since the part of the wheel is “hidden” where the stud sits, it is not possible to align the pallet fork and mark the wheel.

Aligning the pallet fork and mark the wheel can indicate which way you should twist the collet, but to get closer than 2-3 ms is hard.

So, my preferred way is just to take the wheel of, mark the position for the stud and give it a go. You have 50% change that you are twisting the collet the right way on your first attempt.

That’s all folks.

Stay tuned for new adventures!

Well done Rune, made things very clear for us newbies.

Thank you, that was my purpose 🙂